Rethinking Quality Assurance

How a simple process made our projects smoother faster, and just plain better.

If you’ve ever worked in a small A/E firm, you know the dance: tight deadlines, limited staff, and that delicate balance between delivering great work and not drowning in it. Quality control is supposed to be the safety net. Too often, though, it becomes a last-minute scramble, or worse, a box we check because we ran out of time.

We decided to change that.

The Problem We Kept Seeing

Our team is good at design, coordination, solving weird client puzzles, all of it. But the QC process? It was informal. Inconsistent. Personality-driven.

Sometimes we caught everything; sometimes we caught most things; sometimes the thing we didn’t catch really mattered.

We didn’t need a big, bureaucratic manual. We needed something simple, dependable, and built for how we actually work.

Recognizing the challenges of unnecessary revisions, client comments, and internal stress, our team set out to develop a QC process that is structured, repeatable, and adaptable without introducing unnecessary complexity or administrative burden.

The biggest shift wasn’t a form or a checklist, it was mindset.

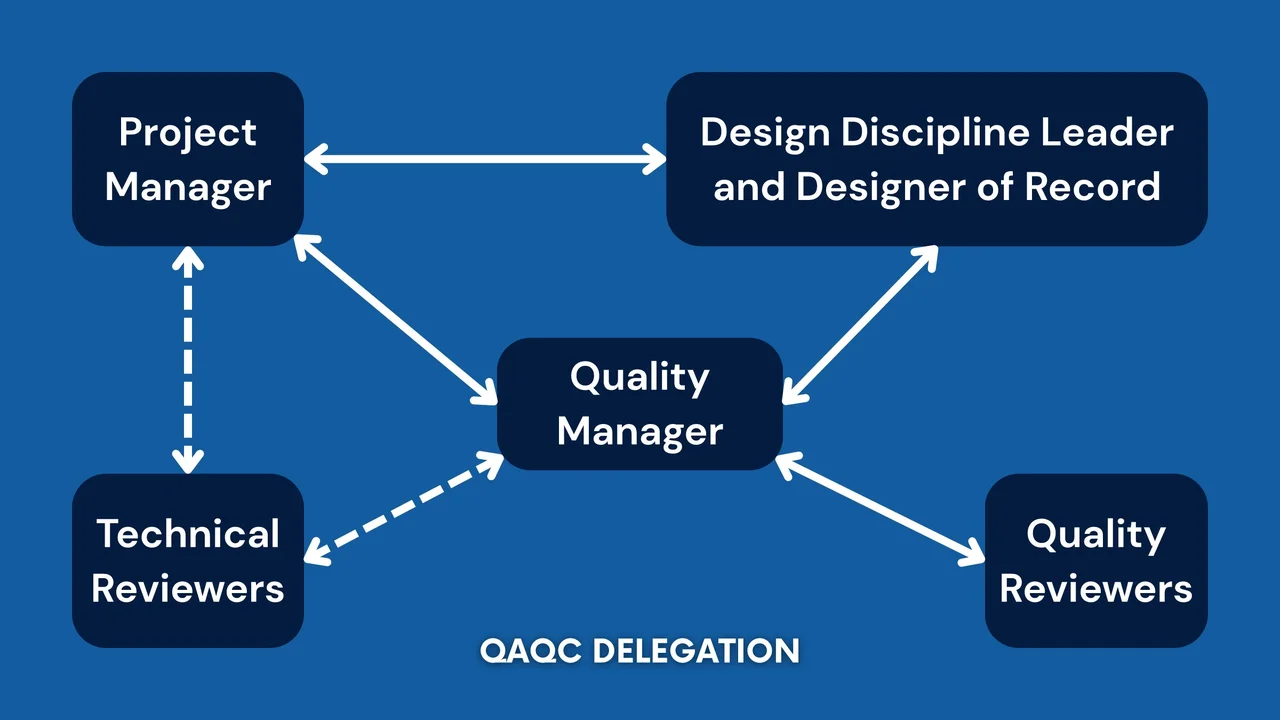

We built a process with just a few essential parts:

1.Start QC Early

Our QC now begins early in the design phase and continues through Document Development. Addressing coordination issues and inconsistencies at earlier stages reduces the risk of compounded errors later. Little course corrections we make early on save us hours later.

2. Holistic, Cross-Discipline Review

Rather than assigning reviewers to specific disciplines or formal pairings, our QC process encourages reviewers to evaluate the submission as a whole. Internal reviewers and external consultants are asked to bring fresh perspective, reviewing documents for clarity, coordination, and consistency across disciplines.

This approach recognizes that many issues arise at discipline interfaces rather than within a single technical scope. By empowering reviewers to comment beyond their primary area of expertise, coordination gaps and inconsistencies are more likely to be identified early.

Subconsultants are similarly encouraged to provide additional eyes during the reviews, supporting a collaborative and comprehensive QC effort rather than a narrowly focused check.

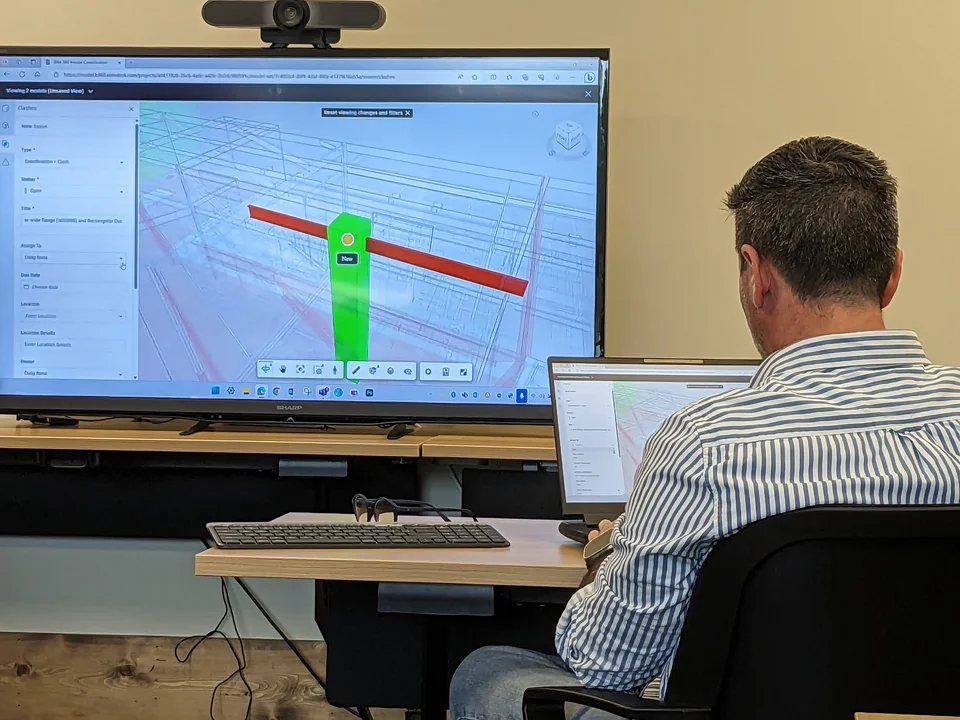

3. Standardized Digital Review Workflow

QC reviews are conducted using a standardized digital workflow within Bluebeam. All reviewers follow a consistent, short, clear convention to clearly distinguish markups, corrected items, and completed responses. Not a mega-page manual. Just the essentials: what must be there, what must match, what must be verified.

This standard allows teams to quickly understand the status of comments, minimizes miscommunication, and provides a clear visual record of the QC process.

4. Leave a Paper Trail (The Useful Kind)

Because all feedback is captured directly within the document set, coordination across disciplines is streamlined and review history is preserved.

QC efforts are recorded in a simple tracking form noting review dates, reviewers, and corrective actions. This documentation supports accountability and provides a valuable reference for future projects without creating unnecessary administrative work.

5. Review the Reviewers

At key milestones, the QC process itself is reviewed. Client feedback, internal efficiency, and project outcomes are evaluated to identify opportunities for refinement and continuous improvement.

Does It Work? Absolutely.

Where this process has been implemented, the results have been tangible:

- Fewer client comments

- A calmer, more predictable document-prep phase

- More on-time submissions

- Fewer project delays

- And—believe it or not—reduced project hours

In one example, we budgeted 1,837 hours but delivered in only 1,390. A major win in both efficiency and sanity.

“Our interactive platform has greatly improved our design products at each submission; ultimately shortening schedules and eliminating change orders during execution. Our partners and our clients alike have remarked on its convenience and noted the higher quality of our submissions early on.” - Mike McCourt, Atriax's Senior Project Manager and Director of Special Projects

Looking Ahead

It’s not fancy. It’s not heavy. It’s not full of jargon.

It’s human.

It acknowledges how small firms actually operate: we wear multiple hats, deadlines overlap, and there’s no “QC Department” waiting in the wings. Our process is built to fit into normal work life instead of fighting it.

The Bigger Payoff

The real benefit hasn’t just been fewer errors. It’s the shift in culture.

People talk more. They look out for each other’s work. No one feels singled out or inspected; they feel supported. And clients feel the difference.

They see cleaner submissions and smoother coordination. That builds trust, and trust builds long-term relationships.

We’re still refining. We’re still learning. But we’re onto something powerful.

Quality isn’t a box. It’s a rhythm. And once you get the rhythm right, the rest tends to fall in place.

About the Authors

CADD Tech Mary Moorer, Architect Chris Cervantes, and Civil Engineer Will McCarrick, PE, are not only the authors of this blog, but the great minds behind implementing the QA/QC process at Atriax. Through their departments and projects, these three professionals strengthen our process and are the backbone to how we rethink QC.